Services for your resistance welding needs

See all the services Techno-Control offers for your resistance welding (e.g. spotwelding) needs, from machines to training, technical advice and more.

Calibration of measuring devices

We offer the calibration service for your measurement tools. You will be given a certificate and a confirmation label.

Resistance welding course

Offered by our team, the benchmark in the field of resistance welding, the four-hour training is an undeniable asset for your team.

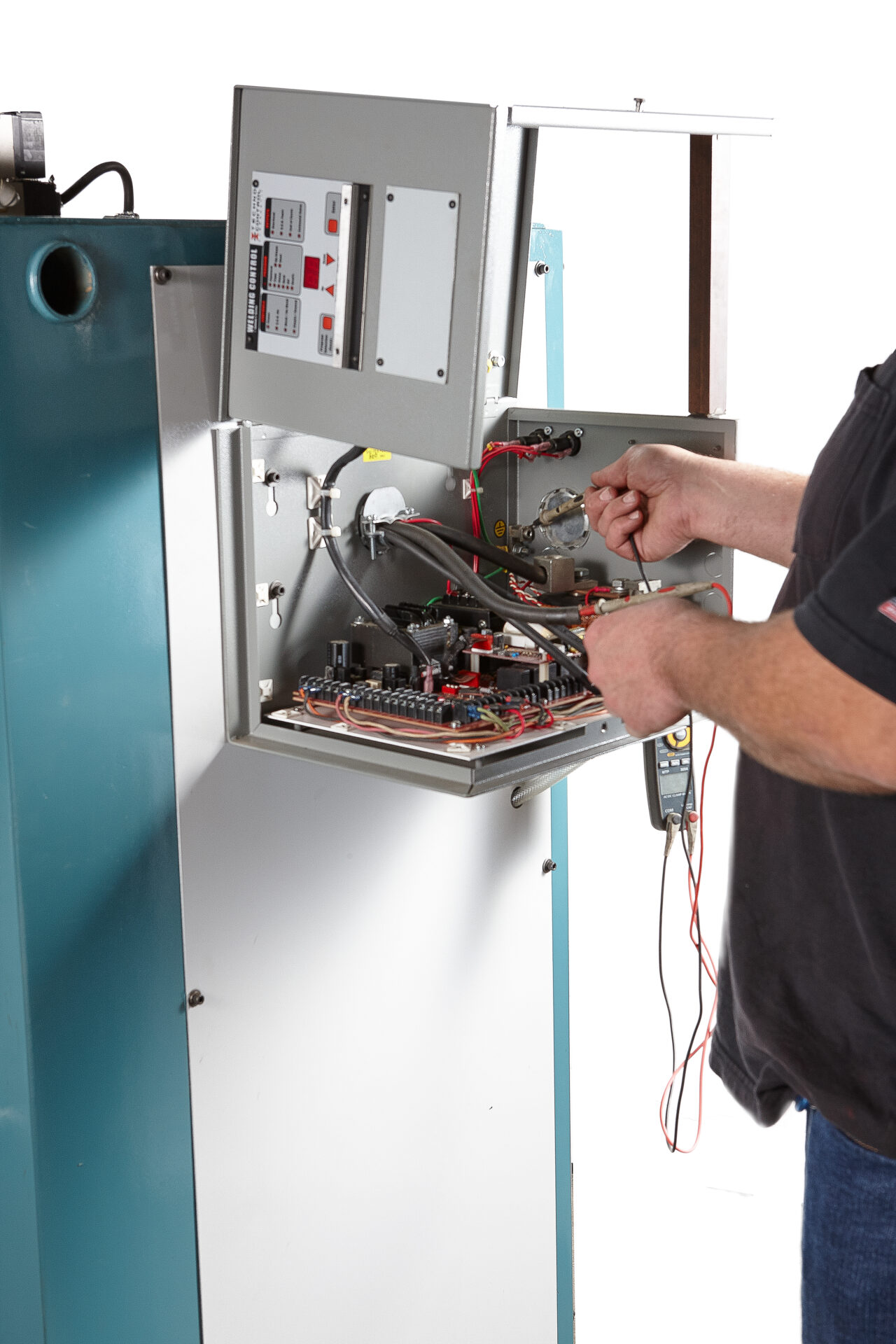

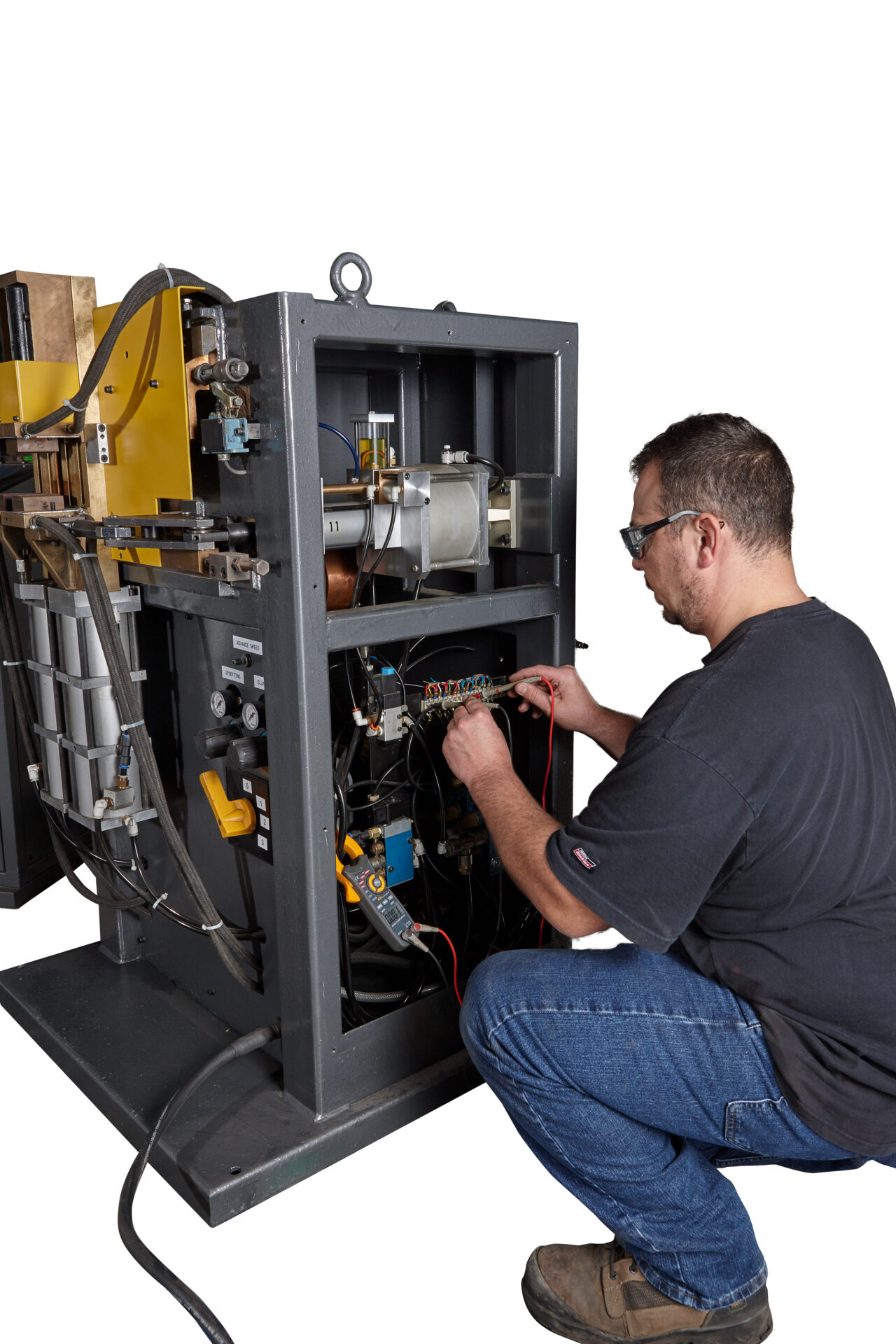

Repair and maintenance service (spotwelder)

We offer our qualified technicians to come to your facilities for repair and maintenance services on your spotwelders and other resistance welding machine.

Resistance welder rental

Resistance welder rental allows you to have access to quality equipment, whether for one-off production or to avoid a production stoppage in the event of a failure on your equipement.

Preventive maintenance (spotwelder)

This exhaustive diagnosis makes it possible to detect a possible breakage, thus avoiding possible production stoppages. Ideally to be done on an a hoc basis once or twice a year.

Descaling

Descaling is to be done every two years. It dissolves the lime in the cooling passages and keeps the optimum performance of your resistance welder.

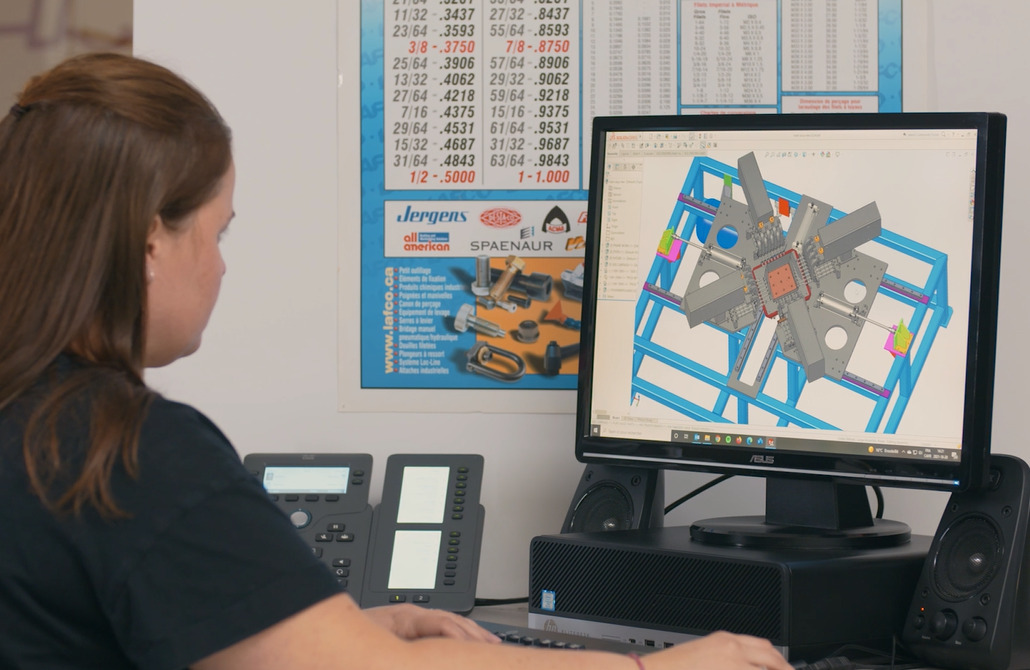

Technical service on resistance welding

The Techno-Control family is proud to offer its customers technical service and advice for resistance welding.

Resistance welder remanufacturing

Refurbishment according to the rule of the art of your machine, which can be complete or partial.

Performance certification

The performance certification service is offered for both your resistance welders and your measuring devices and validates that your devices offer flawless repeatability.

YOU HAVE QUESTIONS? WE HAVE ANSWERS!

I have a hard time welding and I don't know much about my machine. Can you help me?

It will be our pleasure to help you quickly. However, we advise you to go to training in order to fully understand the process. Your production will benefit greatly.

My electrodes get hot very quickly, wear out prematurely and my welds are inconsistent. Can you help me?

It is necessary to check the gallonage. If you are not getting 1.5 gallons per minute, it is likely that a descaling is necessary. Contact us to schedule a service call.

I would like to make a maintenance plan for my machine. What would be the steps to follow?

Since you are working with special machinery, we recommend that you have a preventive maintenance contract with us.