Electrodes

Here you will see the full range of electrodes available on the market. Whatever configuration you need, we will have the solution for you, even if it means creating a custom electrode!

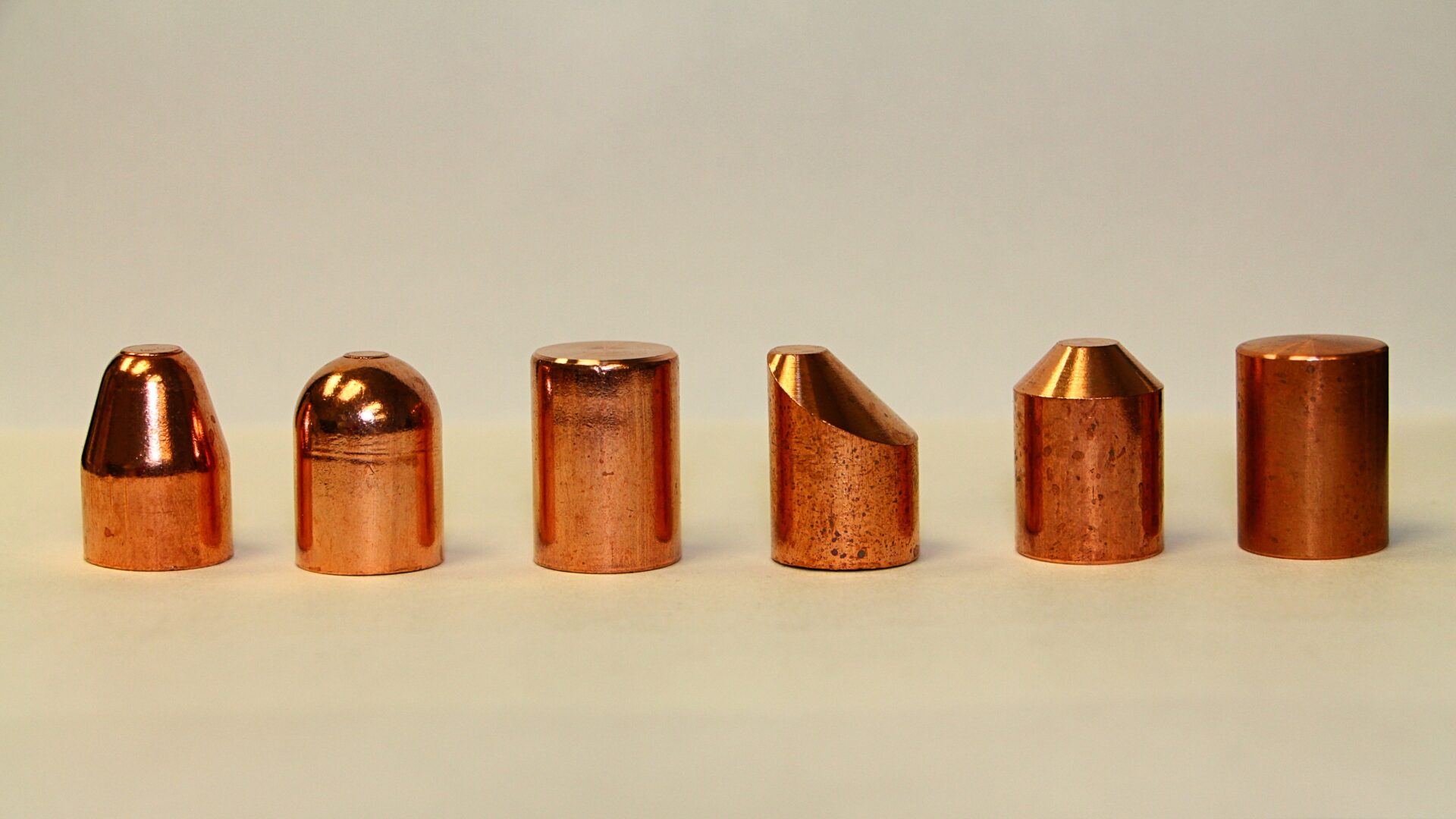

Straight electrode

Straight electrodes are the most common model. Several nose profiles are available.

Single bend electrode

Single bend electrodes are cold formed with straight electrodes and do not have a cooling tube.

Double bend electrode

Double bend electrodes are cold formed from straight electrodes and usually come with a cooling tube.

Back-up electrode

The flat surface electrode offers a round or rectangular welding surface as well as versatility for different applications. Several sizes are available.

Irregular electrode

Irregular electrodes give you access to unique electrode designs that have been standardized. They are less expensive than custom electrodes.

Female cap electrode

They are used for sustained production. Combined with a male extension, they only allow the heading to be changed when used.

Male cap electrode

They are used for sustained production. Combined with a female extension, they only allow the heading to be changed when used.

Male shank for female cap electrode

Used with a female cap electrode, the male extension allows you to find a length of electrode without having to change the complete assembly.

Female shank for male cap electrode

Used with a male cap electrode, the female extension allows you to find a length of electrode without having to change the entire assembly.

Custom electrodes

It will be our pleasure to make your ideas a reality by creating the electrode that will perfectly meet your expectations and your needs.

Radius bend

They come with 5RW taper and are used with a screw-on adapter to provide a solid assembly.

Swivel electrodes

They make it possible to compensate for a minor misalignment. They are used for their aesthetic function because they make it possible to limit the welding mark on a part.

Tungsten

They have the quality of having a very resistant contact surface. They are mainly used when welding nuts or threaded rods.

Nut weld

These electrodes allow you to weld hardware that has spatter. They have a tungsten surface to extend their durability.

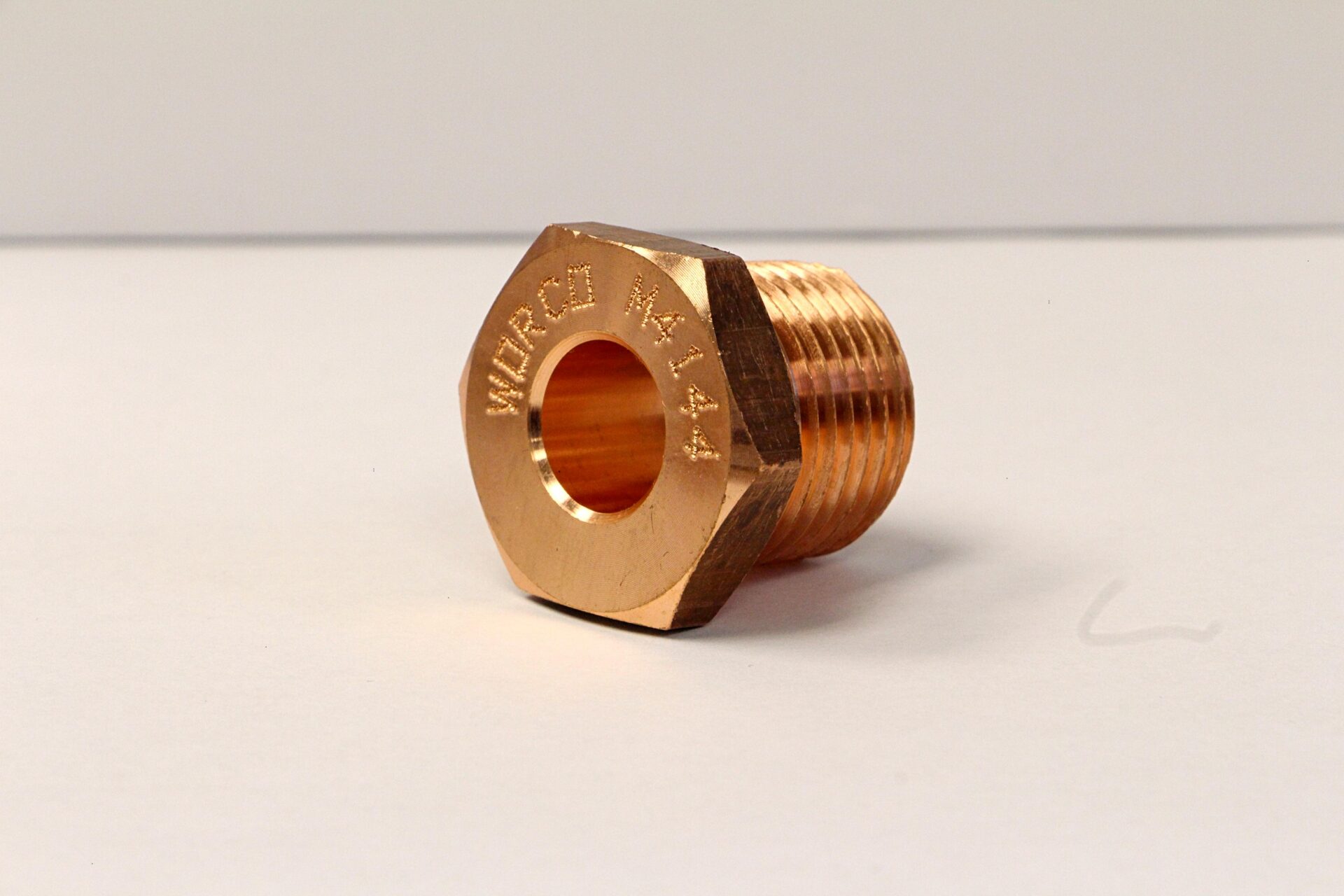

Male taper to female taper adapters

They allow switching from one size of cone to another without changing the electrode holder.

Male straight thread to female taper adapter

They mainly allow you to increase the life of your electrode holder since the wear is mainly suffered by this part.

Male pipe thread to female taper

They mainly allow you to increase the life of your electrode holder since the wear is mainly suffered by this part.

YOU HAVE QUESTIONS? WE HAVE ANSWERS!

Is it possible to use two different electrodes on one machine?

Yes. It will be our pleasure to help you get the best possible productivity depending on the application you need. Contact us!

How often should the electrodes be changed?

There are several variations which prevent us from giving you an exact frequency because each situation is unique. It depends on the settings on your welder, the material used, the adequate cooling, etc. It is also possible to extend the life of the electrodes by using a file, a manual dresser or a pneumatic dresser. We suggest that you contact us to validate all the factors to optimize the durability of your electrodes. It will then be possible to subsequently determine a frequency of change on trial.

Is it possible to weld galvanized steel?

Galvanized steel can be welded. We have technologies that allow you to optimize your process. Welding this material can be difficult for operators as well as equipment. Functions on the controller such as the pulse allow the zinc to be expelled and then welded steel to steel in a single action. Electrodes with impregnations can also make a big difference on your production, the quality of the welds and the transfer of material to your electrodes.